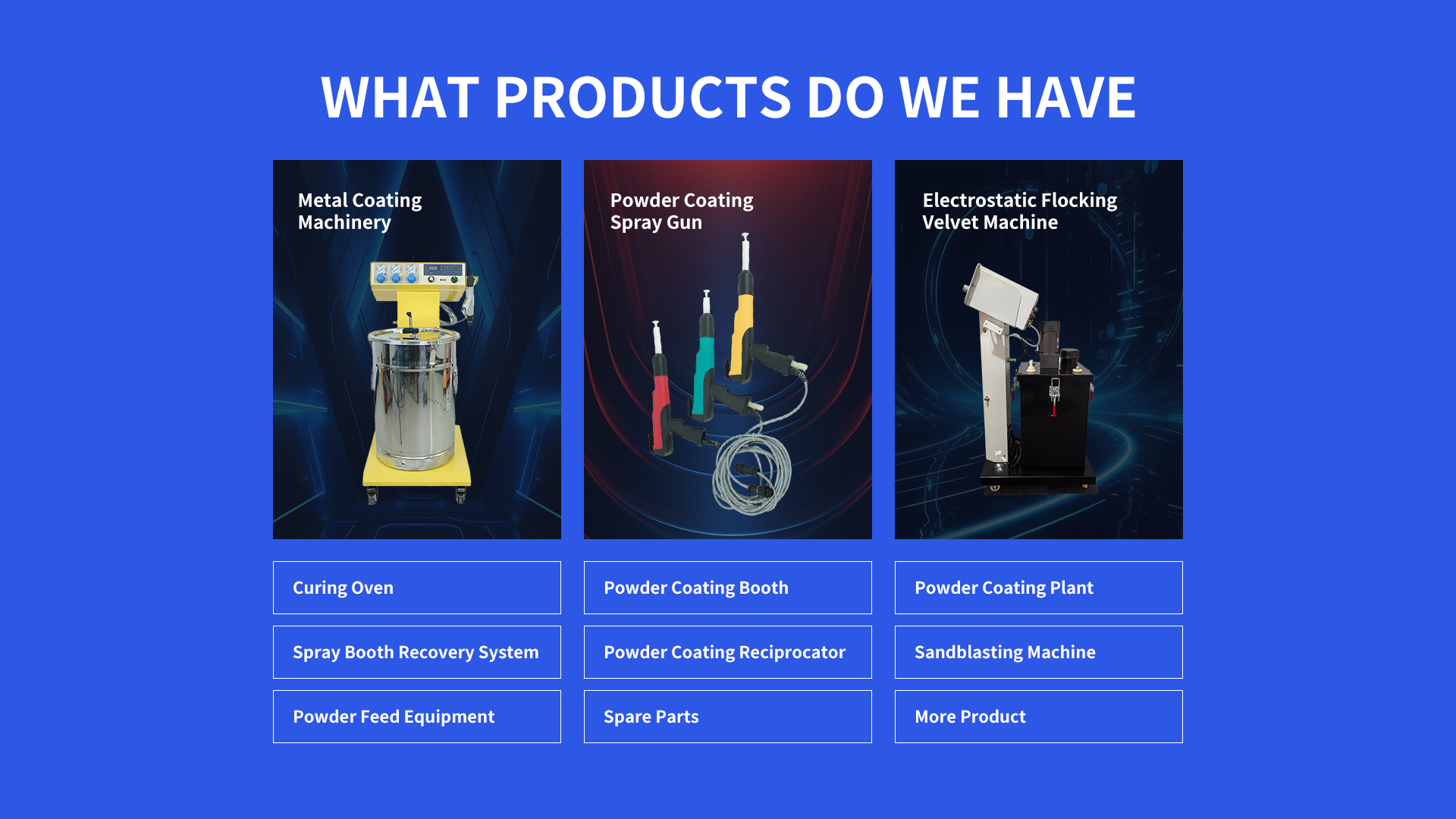

Powder Coating Spray Gun has been evolving continuously, bringing new features and improvements to the coating industry.

The latest

Powder Coating Spray Gun come with enhanced electrostatic charging technologies. These advanced systems provide a more consistent and stronger charge to the powder particles. This results in improved powder adhesion and a more uniform coating even on complex shapes. For instance, in coating intricate metal sculptures, the new guns can ensure that every detail is evenly covered.

The construction of modern

Powder Coating Spray Gun has also seen significant improvements. They are now made with lightweight yet durable materials, making them more comfortable to use for extended periods. The powder hoppers are designed with better sealing mechanisms to prevent powder leakage and ensure a more stable powder supply. The nozzles have been refined to offer a wider range of spray patterns, from a fine mist for detailed work to a broad spray for large surfaces.

In terms of performance, the new generation of

Powder Coating Spray Gun offers higher coating speeds. This is achieved through optimized powder delivery systems and more efficient air flow designs. The guns also have better powder recovery capabilities. They can capture and recycle unused powder more effectively, reducing material waste and costs.

The application areas of these innovative

Powder Coating Spray Gun have expanded. In the electronics industry, they are used to apply protective and insulating coatings on circuit boards and microchips. In the renewable energy sector, they coat components of solar panels and wind turbines, providing protection against harsh environmental conditions. In the architectural industry, they are used to coat metal facades and decorative elements, giving buildings a unique and durable finish.

When using these advanced

Powder Coating Spray Gun, operators need to be trained on the new features. The digital controls and adjustable settings require a certain level of technical knowledge. For example, the ability to program different coating recipes for specific products is a valuable but complex function.

Maintenance of these high-tech

Powder Coating Spray Gun is more sophisticated. The advanced electronics and precision components need regular calibration and cleaning. The software that controls the gun's functions may need to be updated periodically to ensure optimal performance. The filters and sensors should be checked and replaced as needed.

Some challenges with these new

Powder Coating Spray Gun include the initial cost of investment, which is higher due to the advanced technology. However, the long-term benefits in terms of quality and productivity often justify the expense. Another issue is the need for more specialized training for operators, but this can be addressed through comprehensive training programs provided by manufacturers.

In conclusion, the continuous innovation of

Powder Coating Spray Gun is driving the coating industry forward. Their new features and improved performance are opening up new opportunities and enhancing the quality and durability of coated products in a wide range of industries.

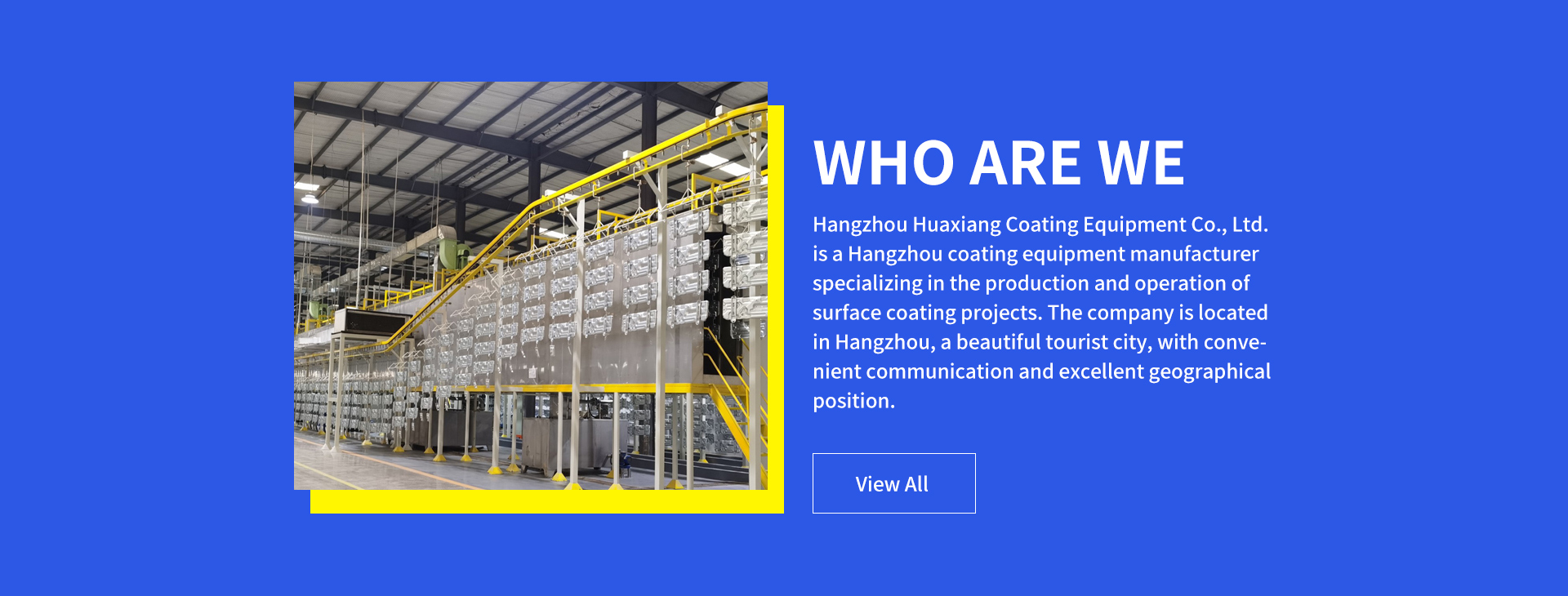

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com